B1 Fire Stop Expanding Foam

A one component polyurethane foam designed for sealing joints in walls and service openings to prevent the passage of smoke and fire. The foam can provide up to 4 hours fire resistance. For improved fire resistance use in conjunction with JCP Fire Rated Silicon (JFIRESIL) or Fire Rated Mastic (JFIREMAS)

Suitable for use in connection with most construction materials and cures by contact with moisture in the air.

The Foam provides excellent heart resistance, sound absorption, high ageing resistance and is resistant to mould and fungal attack.

Uses

Typical applications include, horizontal and verical joints, ductwork, pipe work and services through walls and floors and sealing around doors and windows. The foam can also be used for sealing gaps in building heat insulation and fixing and insulation of wall panels.

Limitations

Polyurethane foam will not adhere to polythene, silicon and Teflon.

Application

Only use in temperatures between +5°C and +30°C

1. Surfaces to be free from grease, dust and loose material. 2. Moisten surfaces well before use, this improves adhesion and cell structure of the cured foam. 3. Shake the can well before and at intervals during use. 4. Remove cap and attach nozzle (Hand Held) or screw into applicator (Gun applied). 5. Turn the can upside down. 6. Fill the cavity approximately half full and spray the foam with water. For large voids build up foam in layers and spray foam with water between each layer.

Notes FIXING:- When fixing door and window frames use wedges to hold the frame in place until foam is full cured, approx 24 hours.

FINISHING:- Cured foam can be cut, sanded, plastered and painted. The foam should be painted or sealed within 7 days if exposed to sunlight as it is not resistant to ultra-violet light.

CLEAN UP:- Uncured foam can be removed with JCP Polyurethane cleaner (JF500C). Cured foam can only be removed nechanically.

B2 Expanding Foam

Product

JCP Gun Grade and Hand Held B2 Foam with CFC free propellant is a one component, self expanding, ready to use polyurethane foam. It contains CFC free propellants which are completely harmless to the ozone layer.

It has a fire rating to B2 (DIN4102-Part 2) and has been tested and approved for sound proofing by "ift Rosenheim"

Application Areas

Installing of window and door frames.

Filling of cavities

Sealing of all openings in roof construction

Creation of a soundproof screen

Sealing around pipes and cables

Improving thermal insulation in cooling systems

Characteristics

Excellent adhesion on most substrates (except PE, PP and Teflon)

High thermal and accoustic insulation

Very good filling capacities

Excellent mounting capacities

Excellent stability (no shrink or post expansion)

Very precise application with gun applied system

Application

Shake the aerosol can for at least 20 seconds. Fit the gun on the adaptor or screw on nozzle. Moisten surfaces with water spray prior to application. Fill holes and cavaties for 65%, as the foam will expand.

Repeat shaking during the application. If several layers are required, repeat moistening with water between each layer. Fresh foam can be removed using JCP Polyurethane cleaner or acetone.

Cured foam can only be removed mechanically. Working temperature +5°C to +35°C. (+20°C to +25°C recommended)

Remarks

Work in layers and moisten after each layer

Cured PU-foam must be protected from UV-radiation by painting or applying a layer of sealant (silicone, MS Polymer, acrylic and PU sealant)

For fire barrier applications foam must be used with JCP Fire Rated Silicone or Intumescent Mastic.

Follow the cleaning and storage instructions included in the Applicator Gun box.

Health and Safety recommendations

Apply the usual industrial hygiene

Wear gloves and safety goggles

Removed cured foam by mechanical means only, never burn away

Consult the label for more information

Approvals

Fire Rating B2: Prufzeugnis P-SAC

02/1V-010, MFPA Leipzig

Prufzeugnis Nr167 18612 to DIN52210

"Fugenschalldammung", ift Rosenheim

B3 Expanding Foam

Product

JCP B3 Foam with CFC free propellant is a one component, self-expanding, ready to use polyurethane foam. It contains CFC free propellants which are completely harmless to the ozone layer.

Application Areas

Installing of window and door frames.

Filling of cavities

Sealing of all openings in roof construction

Creation of a soundproof screen

Sealing around pipes and cables

Improving thermal insulation in cooling systems

Characteristics

Excellent adhesion on most substrates (except PTFE, PE and PP)

High thermal and accoustic insulation

Very good filling capacities

Excellent mounting capacities

Excellent stability (no shrink or post expansion)

Very precise application with gun applied system

Application

Shake the aerosol can for at least 20 seconds. Fit the gun on the adaptor or screw on nozzle. Moisten surfaces with water spray prior to application. Fill holes and cavaties for 65%, as the foam will expand.

Repeat shaking during the application. If several layers are required, repeat moistening with water between each layer. Fresh foam can be removed using JCP Polyurethane cleaner or acetone.

Cured foam can only be removed mechanically. Working temperature +5°C to +35°C. (+20°C to +25°C recommended)

Remarks

Work in layers and moisten after each layer

Cured PU-foam must be protected from UV-radiation by painting or applying a layer of sealant (silicone, MS Polymer, acrylic and PU sealant)

Follow the cleaning and storage instructions included in the Applicator Gun box.

Health and Safety recommendations

Apply the usual industrial hygiene

Wear gloves and safety goggles

Removed cured foam by mechanical means only, never burn away

Consult the label for more information

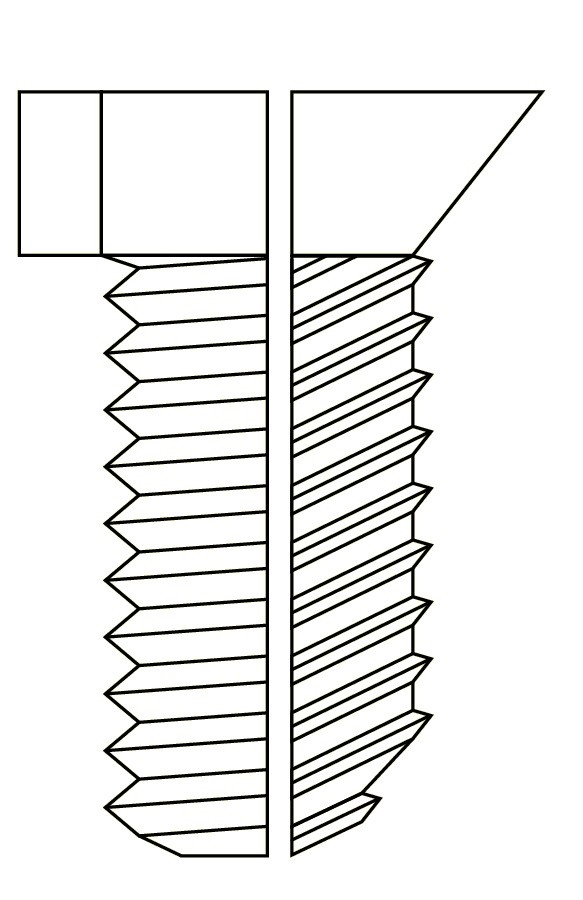

Budget Applicator Gun

Product

A cost effective gun for use with the gun grade expanding foam.

Professional Applicator Gun

Product

A robust gun for use with the gun grade expanding foam.